These are some examples of our project experience. Please download the application notes and contact us to discuss your specific project.

Applications

Air flow control in Effluent Treatment

Sewage treatment is the process of removing contaminants from wastewater, primarily from household sewage. It includes physical, chemical, and biological processes to remove these contaminants and produce environmentally safe treated wastewater An important stage of most treatment processes is the…

Food Additive Dosing

Accurate dosing of additives is a feature of the modern food production processes. Coriolis controlled dosing systems offer an accurate repeatable method to add vitamins, colours, preservatives etc. to food products Flowcon utilise technology from its partners to provides additive…

Environmental Monitoring of Aseptic Facilities

An environmental monitoring (EM) programme is designed to routinely monitor particulates and micro-organisms in critical areas of a pharmaceutical manufacturing facility; in particular, aseptic processing areas. As indicated by FDA Guidance for Industry, Sterile Drug Products Produced by Aseptic Processing-cGMP1,…

Reactor Flow-Pressure Control

Bronkhorst has developed a specialised combination of electronic pressure and thermal mass flow controllers for automated pressure control of reactor vessels. This standard solution can be applied for low flow lab reactor systems as well as for high flow industrial…

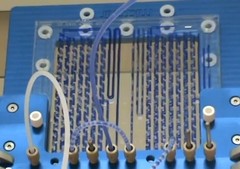

Micro Chemical Reactor- Flow Control

Micro reactors are a developing area in chemical and pharmaceutical synthesis. Unlike standard batch manufacturing processes, microreactors typically operate on a continuous basis with the reactions taking place in small tubes The excellent mass- and heat-transfer properties of microreactors give…

Spray Coating using mass flow pumps

Bronkhorst combine pumps with Coriolis instruments to deliver unrivaled flow control in spraying applications. Existing system’s are susceptible to disruption from pressure variation, changes in density or viscosity of media being sprayed, blocked or worn nozzles. With the Bronkhorst Mass…

Bioreactor Gas Control

Bioreactors are designed to provide a controlled environment for the growth of microorganisms. Ranging in size from small bench top vessels to large industrial size installations, in all cases the gas environment needs to be carefully monitored and controlled. In…

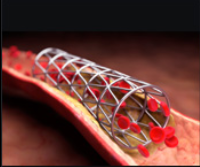

Coronary Stent Coating

The Manufacture of Drug Eluting Coronary stents includes the application of a drug coatings to in a precise and repeatable manner. The drug is normally sprayed onto the stent using a bespoke automated spraying mechanism, in all these applications the…

Precise Mass Flow Liquid Mixing

The accurate and repeatable mixing of liquid ingredients is central in many manufacturing processes. Flowcon have extensive experience working with the industry leaders to designing a number of bespoke solutions to enhance the efficiency of the production process Precision liquid…

Pilot Chemical Plant – Transfer operations

A pilot plant is a small chemical processing system which is operated to generate information used in the design of larger facilities. In Batch processes the transfer of fluids from one vessel to another needs to accurately monitored and controlled….