Environmental Monitoring of Aseptic Facilities

An environmental monitoring (EM) programme is designed to routinely monitor particulates and micro-organisms in critical areas of a pharmaceutical manufacturing facility; in particular, aseptic processing areas.

As indicated by FDA Guidance for Industry, Sterile Drug Products Produced by Aseptic Processing-cGMP1, an environmental monitoring programme can provide information about the quality of the aseptic manufacturing environment in addition to environmental trends of ancillary clean areas.

The data generated through an environmental monitoring programme can demonstrate the effectiveness and performance of certain control practices and systems such as cleaning procedures, personnel hygiene, gowning procedures, operation of the HVAC system and other equipment; this data can also assist the evaluation of the design of the cleanroom.

Thus, an environmental monitoring programme can act as a tool to assess the effectiveness of control measures in cleanrooms and aseptic processing areas

Environmental monitoring involves routine monitoring of the manufacturing environment for the presence of micro-organisms

Active air sampling stations are used to draw a constant flow of air over Agar plates.

The data collected is to provide information on microbiological quality of the environment and to identify any potential contamination hazards. Following data analysis and trending, this information can be used to determine the microbial flora of the environment and to set action and alert limits based on historical data.

To insure accurate comparison and repeatability of samples it is important that the flow rate of air remains within a pre-defined flow range and that any deviations are quickly detected and remedial actions taken

Accurate monitoring of Air flow is therefore critical

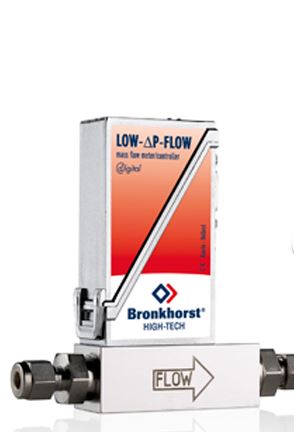

The Bronkhorst range of Low Delta P (Low-Δ-P) instruments has proven to be an effective reliable addition to critical environmental monitoring stations.

The instruments are designed with a low resistance to flow so do not add a significant extra pressure drop to the system

The high accuracy at 1%Full Scale and excellent repeatability of < 0.2% of reading mean that the flow rates measured can be relied on

The compact instrument size insures they can be located at any convenient part of the air flow tubing.

There are a number of signal and control options so the instruments are easy to incorporate into a new or existing station.

The instruments have a configurable alarm output that can be set to signal an out of spec flow event, Totalised flow count, or flow failure.

Flow meter ranges from 0.2mln/min up to 200ln/min are available with either an IP44 or IP65 housing.